In modern construction engineering, hydraulic tools have become indispensable in the installation of steel structures in high-rise buildings due to their powerful operational capacity and efficiency. These tools not only handle heavy lifting, cutting, fastening, and other tasks but also ensure precise execution of each detail in the construction process. This article will explore how various hydraulic tools are integrated into the installation and maintenance of steel structures in high-rise buildings, helping construction teams complete complex tasks more efficiently and safely.

Installation of Steel Beams and Columns

Steel beams and columns are key components of high-rise building structures, and their installation directly impacts the stability of the entire building. In this process, the combination of hydraulic cylinders and hydraulic pumps plays a crucial role. Hydraulic cylinders, driven by powerful hydraulic pressure, lift heavy steel beams weighing several tons to the desired height, while hydraulic pumps provide a steady power source for the hydraulic system. This combination allows not only smooth movement of steel beams but also fine adjustments during installation to ensure perfect alignment with other structural parts.

Traditionally, installing steel beams required a significant amount of manual labor and mechanical equipment. However, with hydraulic tools, the process has become more efficient and safer. Hydraulic cylinders are easy to operate and can make micro-adjustments at various heights, preventing any misalignment that could compromise the structure’s integrity. Therefore, in high-rise buildings, the combination of hydraulic cylinders and pumps significantly improves the accuracy and efficiency of construction.

Fastening Steel Beams and Columns

Once the steel beams and columns are aligned and in place, the next step involves fastening them securely. At this stage, hydraulic wrenches become vital tools for the construction team. These wrenches generate high torque through hydraulic pressure, allowing workers to easily tighten large bolts and nuts. In steel structure buildings, these bolts are used to secure the connections between steel beams and columns, ensuring the stability of the entire framework.

Compared to manual wrenches, hydraulic wrenches are not only more efficient but also provide much stronger torque, preventing issues like loose bolts or improper installation caused by manual operation. The precision and power of hydraulic wrenches make them widely applicable in the fastening tasks of large beam and column structures, reducing labor intensity and completing large volumes of bolting work in a short time, thus speeding up the construction process.

Cable Installation and Connection

As construction progresses, installing the electrical systems becomes a critical phase. High-rise buildings require extensive cable installations for power and communication systems. At this point, hydraulic cable cutters and hydraulic crimping tools play important roles. Hydraulic cable cutters enable quick and clean cuts through thick cables, avoiding the uneven cuts often produced by traditional scissors or saws. For safety and efficiency in electrical systems, ensuring neat cable cuts is essential to avoid the risk of poor connections.

After cutting the cables, hydraulic crimping tools are used to crimp cable ends. These tools apply strong pressure to firmly connect the cable to terminals, ensuring a solid and conductive electrical connection. In large-scale electrical systems, hydraulic crimping tools significantly improve connection quality and are suitable for various wiring scenarios in high-rise buildings.

Steel Structure Hole Processing

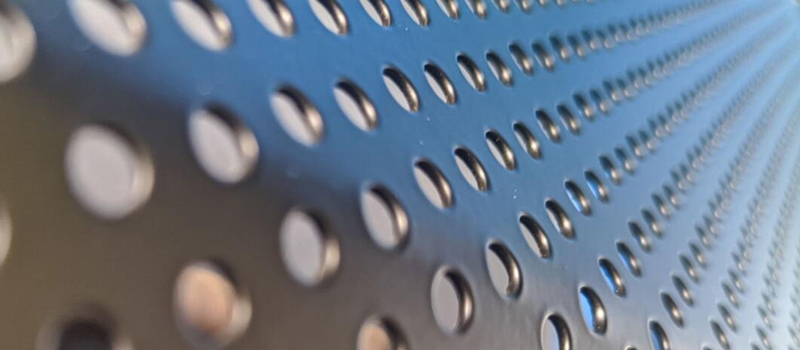

In steel structure construction, it is often necessary to punch holes in steel materials for bolt fixing or connecting other components. Traditional manual hole-punching tools are inefficient and struggle to perform precise operations on high-strength steel. Hydraulic punching machines solve this problem by using hydraulic pressure to quickly and accurately punch holes in steel, ensuring that each hole is positioned and sized according to the construction requirements.

During the installation of steel structures, some beams or columns may need to be temporarily adjusted according to site conditions. In such cases, the high efficiency of hydraulic punching machines is especially important. They can not only quickly complete the punching tasks but also ensure smooth hole edges, preventing damage to the material’s overall strength. Hydraulic punching machines are widely used in bridge construction and high-rise steel structure installations, significantly enhancing construction efficiency.

Removal and Replacement of Old Fasteners

As a building ages, some fasteners may become corroded or overtightened, making them difficult to remove. The hydraulic nut splitter is an ideal tool for solving this problem. The hydraulic nut splitter uses hydraulic pressure to cut through stubborn nuts that are difficult to remove, avoiding damage to the surrounding steel.

During regular building maintenance, the hydraulic nut splitter is used to remove aging nuts, creating the conditions for installing new fasteners. Its use reduces the physical strain on construction workers and prevents accidents caused by forceful removal. This tool plays an important role in maintaining and refurbishing large steel structure buildings.

Dismantling and Pulling Out Old Components

In building renovations or repairs, some old components, such as bearings or fasteners, need to be dismantled. The hydraulic puller can easily extract these tightly fitted components using hydraulic pressure, preventing damage to surrounding materials. In the maintenance of high-rise building elevators and the replacement of building equipment, hydraulic pullers are widely used to dismantle old components, ensuring the smooth installation of new systems.

The use of hydraulic pullers improves the efficiency of dismantling tasks, especially in hard-to-reach areas, where they can achieve safe removal over long distances. Hydraulic pullers are widely applied in the maintenance of construction machinery and the replacement of parts in electrical systems.

The application of hydraulic tools in the installation and maintenance of high-rise building steel structures greatly enhances construction efficiency and safety. Whether it is lifting and installing steel beams, fastening columns, laying cables, processing holes, or replacing old components, hydraulic tools provide efficient solutions. These tools not only reduce the difficulty of manual labor but also ensure the precision and stability of construction. By integrating hydraulic tools, construction projects can complete complex tasks in a shorter time, ensuring the overall quality and safety of high-rise buildings.