Crimping Tools

Hydraulic Crimping Tool, 4~70mm², 8 Dies

Hydraulic Crimping Tool, 10~240mm², 10 Dies

Hydraulic Crimping Pliers, 16~300mm², 11 Dies

Hydraulic Crimping Pliers, 16~240mm², 10 Dies

Hydraulic Crimping Pliers, 16~400mm², 9 Dies

6 Ton Battery Powered Hydraulic Crimping Tool

12 Ton Battery Powered Hydraulic Crimping Tool

3 Ton Battery Powered Hydraulic Pipe Crimper, 6 Dies

10 Ton Hydraulic Crimper Head, 16~300mm²

13 Ton Hydraulic Crimper Head, 50~400mm²

25~55 Ton Hydraulic Crimper Head, 16~1000mm²

12 Ton Hydraulic Crimper Head, 50~400mm²

Crimping is a process that uses a tool or machine to deform materials to seal ring joints or fasteners. Crimping tool is a tool specially designed for making cold weld joints between two wires or a wire and a connector.

There are a large number of connectors and terminals used on wires, so the crimping tools are widely applied in electrical, communications and plumbing industries, and commonly used in network cable (or LAN) laying, cable swaging, PEX tube manufacturing, and so on.

Types of Crimping Tools

There are many different types of crimping tools, and the commonly-used types are hand crimpers, hydraulic crimpers and electric crimpers.

Hand crimpers, also called crimping pliers, are manually operated and generally used for smaller wires. Some hand crimpers also come with the functions of stripping and cutting wire. Therefore, the main function of the wire crimper: strip the wire and insert it into the terminal, and use the crimping pliers to clamp the wire to connect the wire to the terminal.

Hydraulic crimpers, just as its name implies, are operated by hydraulic pump and used for thicker wires because they can be applied more crimping force, such as 8 ton, 9 ton, 10 ton, 12 ton, etc. Hydraulic crimper is usually used with crimping dies of different sizes to crimp cable, wire, connector, lug, etc. Of course, there is also a type of dieless hydraulic wire crimper and you can save the selection of dies and have faster operation. However, the hydraulic crimping tool with dies can be applied for a wider range of wire or cable sizes. Tool.com provides you a series of hydraulic cable wire crimping tools with 8 dies, 9 dies, 10 dies etc., for use with a wide range of wires 4-70mm2, 10-240mm2, 16-300mm2, etc.

The popular electric crimpers are cordless crimping tools, which are operated by rechargeable lithium battery. The battery-powered crimping tool is greatly suitable for heavy duty jobs that need more power. The battery operated cable crimper is lightweight and portable which can be operated with one hand.

There are also remote powered crimping heads, which are powered with external hydraulic pump. Therefore, the hydraulic crimper heads must work with hydraulic pumps, manual or electric hydraulic pumps. The hydraulic crimper heads are suitable for electric overhead lines and underground cable lines.

For the electricians, the most commonly used are the hand crimpers and hydraulic crimping tools. Generally speaking, hand crimpers are used for wires with a cross-sectional area of 35mm2 and below, and hydraulic crimpers for wires above 35mm2.

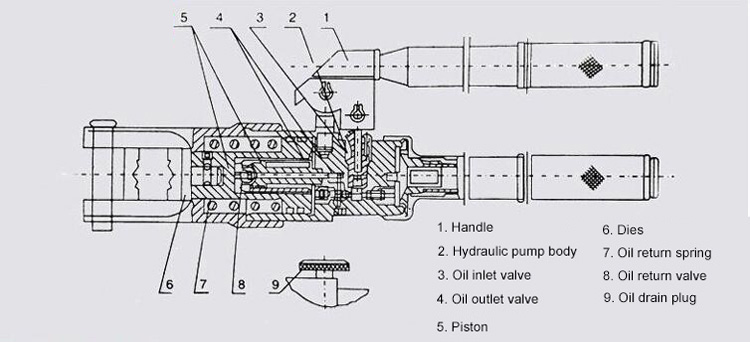

Structure of Hydraulic Crimping Tools

Hydraulic crimp tool consists of an oil tank, a power mechanism, a reversing valve, a pressure relief valve, and an oil pump mechanism. The oil pump mechanism is made up of an oil pump body, high and low pressure oil outlet holes, eccentric shafts, eccentric bearings, driven gears, a pair of high pressure oil pumps, and a low pressure oil pump. The oil pump body is fixed on the oil tank cover, and the high and low pressure oil outlet holes are opened on the oil pump body, connected with the pressure relief valve oil circuit. The eccentric shaft is arranged longitudinally, the upper end pivoted in the center of the oil pump body, and the lower end fixed with eccentric bearing. The driven gear is fixed on the top of eccentric shaft, connected with power mechanism. The high and low pressure oil pumps are suspended on the oil pump body, each of which has an actuator contacting the eccentric bearing. The pump cavity of the high and low pressure oil pumps are respectively communicated with high and low pressure oil outlet holes.

The oil pump mechanism and the power mechanism are connected vertically, which can make full use of space and reduce the footprint, which is beneficial to operation and transportation. Besides, the oil pumping form of high and low pressure oil pumps is changed to the actuating form of eccentric bearing, which has a simple structure, few parts and easy to assemble.

How to Use Hydraulic Crimping Tools?

1. First check whether the crimped terminal matches the wire specification.

2. Choose the suitable crimping dies. For example, if the size of the pressed terminal is 240mm2, then select 240mm2 upper and lower dies.

3. Put the dies into the piston and the die fixing seat.

4. Tighten the oil inlet and return switch in a clockwise direction to repeatedly shake the handle. Watch the dies and when the upper and lower dies touch one place, it means the crimping is complete. If the user does not pay attention to it and continue shaking the handle, the pump will send a clicking sound, that is, the safety protection device is started and the piston stops moving forward. At this time, the oil return switch should be turned counterclockwise, and the piston will return to its original position.

Note: The hydraulic crimper cannot be compressed if the dies are not installed, thus avoiding damage to the piston and jaws.

How to Maintain Hydraulic Crimping Tools?

The daily maintenance of hydraulic crimping tools is as follows:

- Do not shake the pump handle to make the jaws close when the dies are installed. Otherwise, the excessive pressure applied on the jaws can cause jaws cracks or damages. If the jaws are closed without dies due to negligence, you can no longer continue to swing the pump to apply pressure. In this case, release the pressure first.

- Keep hydraulic crimper clean and avoid dust or metal particles, especially the crimper head, dies and indenter.

- Regularly check the amount of oil and use the recommended pure oil. Do not mix various brands or types of oil, otherwise it will cause damage to the oil seal of the hydraulic crimping tool.

Find high quality hydraulic crimping tools at competitive price on Tool.com. Here provide handheld hydraulic crimper and dies set, battery-powered hydraulic crimper and remote-powered hydraulic crimper head (For use with hydraulic pump, we also offer manual and electric hydraulic pumps for choice). All the hydraulic crimping tools are equipped with a certain number of dies, thus applied for a wider range of wire or cable sizes. The maximum crimping range can be up to 400mm2. For the details, please move to the product page, or contact us if you have any questions.