Measuring Tools

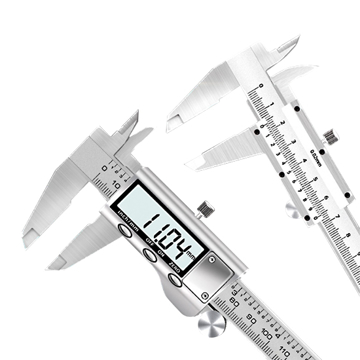

6" (160mm) Distance Measuring Wheel, Digital LCD

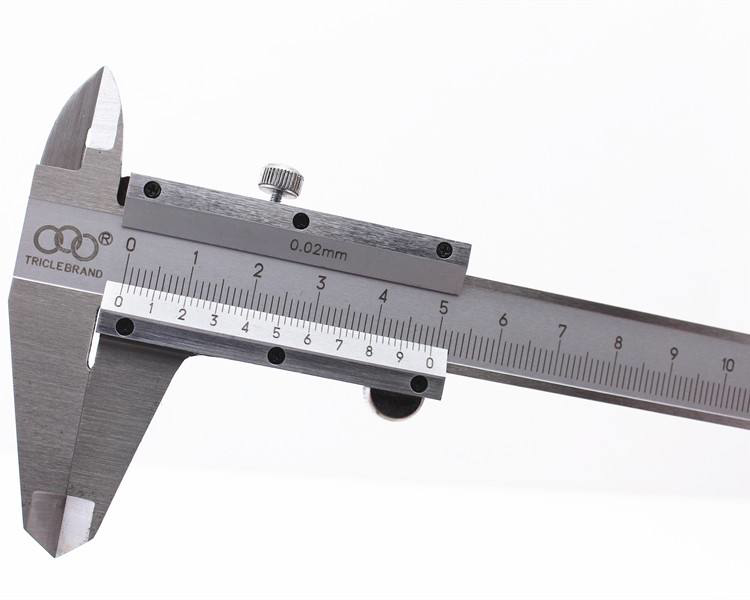

Stainless Steel Vernier Caliper, 6 Inch/ 150mm

Wired Smoke Detector, Network-Connected Fire Alarm

0.01-1mm Metric Feeler Gauge, 18 Blades

0-1000mm Digital Height Gauge, 0.01mm

0-1300μm Coating Thickness Gauge

0-200mm Digital Height Gauge, 0.01mm

0-300mm Digital Height Gauge, 0.01mm

0-500mm Digital Height Gauge, 0.01mm

0-600mm Digital Height Gauge, 0.01mm

2 Line Rotary Green Laser Level

3 Cups Anemometer and Wind Vane, Wind Speed and Direction Meter

30 to 130 dB Wall Mounted Sound Level Meter

3m (10 ft) Easy Read Steel Tape Measure

4 in 1 Wall Mounted Sound Level Meter, 30 to 130 dB

400 Yards Golf Laser Rangefinder, 6X Magnification

9 in 1 OTDR Fiber Optic Tester, 1310/1550nm, 22/20dB

Aluminum 3 Cups Anemometer, Mechanical Wind Speed Meter

Combo Smoke & Carbon Monoxide (CO) Detector, Wireless Fire Alarm

Decibel Sound Level Meter, 17 to 132 dB/25 to 140 dB/45 to 160 dB

A measuring tool is a tool for measuring a certain property. Including length, temperature, time, mass, force, current, voltage, resistance, sound, radio, refractive index and average dispersion. According to its usage, it usually can be divided into two types: General measuring tools and special measuring tools.

Measuring tools can also be divided into mechanical, optical, pneumatic, electric and photoelectric types according to their working principles. However, some modern measurement tools have developed into measurement tools that use the principles of precision mechanics, light, and electricity at the same time and combined with electronic computer technology. Therefore, this classification method is only suitable for measurement tools with a single working principle.

Measuring tools can also be divided into mechanical, optical, pneumatic, electric and photoelectric types according to their working principles. However, some modern measurement tools have developed into measurement tools that use the principles of precision mechanics, light, and electricity at the same time and combined with electronic computer technology. Therefore, this classification method is only suitable for measurement tools with a single working principle.

A measuring tool that can measure the length or angle of various types of work-pieces, This type of measuring tool has the most varieties and specifications, and is also the most widely used, including gauge blocks, angle gauge blocks, polyhedral prisms, sine gauges, calipers, micrometers, dial indicators, multi-tooth indexing tables, comparators, and laser length measuring instruments , tool microscope, coordinate measuring machine, etc.

Generic measuring tools

Common measurement tools are as follows:

Rangefinder

Rangefinder is also called distance meter, which is an instrument used for distance measurement based on the principles of electromagnetic wave, optics, acoustics and has a compact body. Two methods are generally used to measure distance: pulse method and phase method. The process of pulse distance measurement is as follows: the laser light emitted by the range finder is reflected by the object to be measured and then received by the range finder, and the range finder also records the round-trip time of the laser. Half of the product of the speed of light and the round-trip time is the distance between the rangefinder and the measured object. The accuracy of pulse method measuring distance is generally about +/- 1 meter. In addition, the blind zone of this type of rangefinder is generally about 15 meters.

Since the laser is used for distance measurement, and the pulsed laser beam is a monochromatic light source with very concentrated energy, so do not use your eyes to look directly at the emitting port, Do not use the aiming telescope to observe the smooth reflecting surface, so as not to hurt people's eyes. Do not directly aim the launching port of the instrument at the sun during field measurement to avoid burning the photosensitive element of the instrument.

Maintenance

Check the appearance of the instrument frequently and remove the dust, grease, mildew, etc. on the surface in time.

Use a soft dry cloth to clean the eyepiece, objective lens or laser emission window. Scribing with hard objects is strictly prohibited to avoid damage to optical performance.

This machine is a high-precision instrument that integrates optical, mechanical, and electrical. It should be handled with care during use, and it is strictly prohibited to squeeze or fall from a high place to avoid damage to the instrument.

Tape measure

The tape measure can be rolled up because there is a spring inside the tape measure. When the tape measure is pulled out to measure the length, it actually stretches the length of the ruler and the spring.Once the measurement is completed, the spring inside the tape measure will automatically shrink, and the ruler will also shrink under the action of the spring force, so the tape measure will roll up.

Precautions for maintenance and use

- Keep the instrument clean before and after use.

- Don't get severe impact or drop when using.

- Since there is no measuring force pressure device, it needs to be used with proper and uniform measuring force.

- Wipe and clean the surface dust after use.

- Do not twist to prevent breakage during use.

- When in use, it should be straightened and supported on a flat surface to prevent the measurement accuracy from being affected by the sagging of the ruler surface.

Laser rangefinder

The laser rangefinder is an instrument that uses a certain parameter of the modulated laser to measure the distance to the target. The measuring range of laser rangefinder is 3.5~5000 meters. According to the ranging method, it is divided into phase method range finder and pulse method range finder. Pulsed laser range finder emits a beam or a sequence of short pulsed laser beams to the target when it is working. The photoelectric element receives the laser beam reflected by the target, and the timer measures the time from emission to reception of the laser beam, and calculates the distance from the observer to the target. The phase method laser rangefinder detects the distance by detecting the phase difference that occurs when the emitted light and reflected light propagate in space. The laser rangefinder is light in weight, small in size, simple to operate, fast and accurate, and its error is only one-fifth to one-hundredth of other optical rangefinders.

Laser rangefinder operating rules:

- Turn on the switch, turn on the power, the "power、test indicator" is green. Touch the gear selection switch to select the appropriate gear.

- Connect the two current output terminals of the measuring terminal of the meter to the two terminals of the conductor under test with two test wires, and the two voltage input terminals are also connected to the two terminals of the conductor under test.

- The voltage terminal should be located inside the current terminal and as close as possible to the tested product to reduce the error introduced by the lead resistance.

- After wiring, press the TESTE key, the "power, test indicator" is red, and the value displayed on the display is the measured resistance value.

- When the measured conductor is open or the resistance is greater than the selected range, the first digit of the display shows "1", and the last three digits are off.

precaution

- When the under-voltage symbol appears on the display, please replace the battery to ensure that you get the correct test value. Do not throw away the replaced old battery to avoid pollution.

- The instrument should be protected from damp, rain, drop, exposure, etc.

laser level

The laser level is a level that guides the laser beam emitted by the laser device into the telescope tube of the level and emits it along the collimation axis. There are two types of laser level meter: a special laser level meter and a laser device attached to the level meter. It can be used with a level rod equipped with a photoelectric receiving target to perform leveling. Compared with optical level meters, laser level meters have the characteristics of high accuracy, long line of sight and automatic reading and recording. The laser level is an intelligent display device instrument. Its function is to be installed on a moving object, collect signals from the horizon, display the horizon in a larger field of view, and display the movement posture of the object in real time. If the laser level is corrected on the plane, it will be of great significance to prevent space disorientation; in addition, in medical testing, manual signals are used to adjust the position of the laser scanning line, which can perform certain pathological tests on the human brain, and it is also widely used in handicrafts and architectural decoration.

5 maintenance tips for laser level

- The laser level is a precise optical instrument. Correct and reasonable use and storage have a great effect on the accuracy and life of the laser level.

- Avoid direct sunlight and do not disassemble the laser level casually.

- When the laser level malfunctions, it should be repaired by professionals or repair shops familiar with the structure of the laser level.

- Each fine-tuning should be turned gently, not too much force. Lenses and optical films of the laser level are not allowed to touch with hands.

- After each use, the laser level should be wiped clean and kept dry.

Measuring wheel

Measuring wheels are also known as mechanical distance measuring vehicles, digital display measuring wheels, which are widely used in professional surveying and mapping operations, road engineering, pipeline laying engineering, wire and cable engineering and other construction operations measurement and evaluation. It can be used for the construction measurement of garden landscape and golf course, the measurement of the distance and location of traffic accidents, and the measurement of farmland construction and management. The mechanical distance measuring wheel adopts high-quality precision design, small, light and durable. The 300MM measuring wheel is easy to use, what you need to do is just to press the reset button of the counter and then the count increases when the measurement goes forward and decreases when it goes backward.

Point-to-point measurement method

Place the distance measuring wheel tool on the ground, so that the point pointed by the positioning pin coincides with the starting point.

Move the distance measuring wheel until the point pointed by the positioning pin coincides with the end point.

Record the measured reading of the dial, this reading is the correct distance.

Tips for measuring accuracy of measuring wheels

The distance measuring wheel has very high requirements for measurement accuracy and stability. The biggest error source of the measuring wheel is the deformation of the measuring wheel tire through online investigation. Many factors such as temperature changes, air pressure changes, and applied pressure changes are prone to non-negligible deformation of the tires of the gauge wheel, which greatly affects the measurement accuracy. Moreover, the distance measuring wheel is used for medium and long distance measuring work, and the small deformation will always be superimposed in the rolling of the tire circle by circle, and the calculated measurement length will cause a large measurement error. Therefore, the measuring wheel must be strictly tested before the measurement work to ensure the reliability of the measurement data.

Vernier calliper

Vernier calliper is a measuring tool for measuring length, inner and outer diameter, and depth. The vernier caliper consists of a main ruler and a sliding vernier attached to the main ruler. The main ruler is generally in millimeters, and there are 10, 20 or 50 divisions on the vernier. According to the different divisions, the vernier caliper can be divided into tenth-degree vernier caliper, 20th-degree vernier caliper, fifty-point-degree vernier caliper, etc. The vernier is 9mm with 10 scale, 19mm with 20 scale, and 49mm with 50 scale.

Precautions for use

Wipe the measuring claws clean with a soft cloth, close them together, and check whether the vernier is aligned with the zero mark of the main ruler. If it is aligned, it can be measured: if it is not aligned, the zero error should be recorded: the zero scale line of the vernier is called positive zero error on the right side of the zero scale line on the ruler body, and the negative zero error on the left side of the zero scale line on the ruler body (this The method of specifying the file is consistent with the number axis. The origin is positive on the right and negative on the left. When measuring, hold the ruler with your right hand, move the cursor with your thumb, and hold the object with the outer diameter (or inner diameter) to be measured in your left hand, so that the object to be measured is located between the outer measuring claws, and when it is in close contact with the measuring claws, you can reading.

Special measurement tools

- A measuring tool used to measure a certain type of geometric parameters, shape and position errors (see form and position tolerance) It can be divided into:

Straightness and flatness measuring tools, common ones include straightedge, flat ruler, flat crystal, level, autocollimator, etc.; - Surface roughness measurement tools, they commonly are surface roughness samples, light section microscope, interference microscope and surface roughness measuring instrument, etc.

- Roundness and cylindricity measuring tools, including roundness meter, cylindricity measuring instrument, etc.

- Gear measuring tools, common gear comprehensive inspection instrument, involute measuring instrument, circumferential section measuring instrument, lead meter, etc.

- Thread measuring tools.

Other special measuring tools

It is only suitable for measuring tools that measure the size, surface roughness, shape and position error of a specific workpiece. Common ones are automatic inspection machines, automatic sorting machines, single-size and multi-size inspection devices (see automatic measurement).

TOOL.com is a multinational shopping website, where you can find the products that you need on no matter for daily life or factory work, and products are wholesale, so it is affordable for you. Check the link for further imformation!