Magnetic Drill

Magnetic Drill Press, 16mm Twist Drill Bit, 1350W, 12500N

Magnetic Drill Press, 23mm Twist Drill Bit, 1500W, 13500N

Magnetic Drill Press, 28mm Twist Drill Bit, 1600W, 14500N

Magnetic Drill Press, 32mm Twist Drill Bit, 2400W, 18000N

Magnetic Drill Press, 35mm Annular Cutter, 1500W, 10000N

Magnetic Drill Press, 50mm Annular Cutter, 1500W, 13500N

Wholesale magnetic drill press tools on Tool.com store with affordable price. Feature with differnt strong magnetic adhesion such as 10000N, 13500N, 18000, twist drill bit of 16-23mm diameter or annular cutter of 35-50mm, operates at 50Hz or 60Hz 110V / 220V / 240V AC rated voltage. Portable magnetic drill is a high performance and reliable drilling machine to produce superior holes quickly and efficiently, a construction tool perfect for use in heavy-duty industrial environments and fabrication work. The more you buy, the more you save.

Magnetic drill press

Magnetic drill is a kind of portable magnetic drill press with magnetic base (electromagnetic or permanent magnet). It is a metal processing construction tool which can accurately drill, tap and twist holes on the steel structure, which is commonly known as the drilling rig adsorbed on the steel structure. Magnetic drills are faster, lighter and more accurate than hand drills. The magnetic drill press is used for steel or other magnetic materials. It can reach the accuracy of 0.01 mm to 0.05 mm when working on steel or other magnetic materials. The drill bit of this construction machine is usually made of high speed steel (HSS) or tungsten carbide (TCT). It combines a stable magnetic foundation and a large diameter drill bit with low speed to help resist or reduce torque. Rotary tools such as twist drill, ring cutter and milling cutter can be used.

Working principle

Magnetic drill press is a kind of movable and high-efficiency tool which can absorb the drilling frame and rotary drilling mechanism on the surface of iron and steel workpiece by electromagnetic principle through magnetic base.

The magnetic drill press is mainly divided into two parts.

The first part: Magnetic base.

The function of the magnetic base is that after being electrified, the magnetic drill generates a magnetic suction force of thousands of kilograms perpendicular to the bottom surface of the magnetic base through the electromagnetic effect, so that it can be firmly adsorbed on the processing surface of steel plate or structural parts, playing the role of fixing the machine. The stronger the magnetic suction force is, the more stable the frame of the magnetic drill is and the higher the drilling accuracy is.

The second part: Drilling. Drilling is divided into two parts.

◆ Fixed part. When drilling, it is fixed and its main function is to control the motor, such as switch speed control gear, etc.

◆ Moving part. The whole moving part is moved up and down by manual rotation of black three-star frame, so that the drill bit is connected with the steel structure. Turn on the motor start switch, the rotor in the machine motor rotates at high speed, and drives the transmission shaft to rotate through the transmission gear set to drive the drill bit to rotate. The drill is used to cut and drill holes at the parts that need to be drilled. Compared with flame cutting, the hole drilled by magnetic base has high precision and belongs to physical cutting, which will not produce chemical reaction and deform the material.

Installation of drill

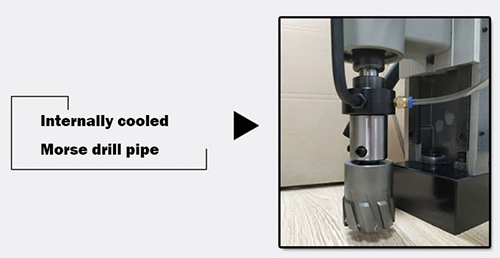

1. Install the drill bit: When installing the drill bit and the pin head with keyless converter, make sure that the drill bit is installed correctly. Use the left hand to screw the quick change bit head to the end in a counter clockwise direction. With the right hand, align the drill bit vertically with the hole of the quick change clip head and push it up to the end. Then, with the right hand, gently rotate the drill bit until the "click" sound is heard. If it is necessary to remove the drill bit, use the left hand to screw the quick change bit head to the end in a counterclockwise direction, and pull out the drill bit vertically with the right hand.

2. Feed tightness adjustment: After using for a period of time, if you find that the feed stroke of the drill bit is not controlled by the handle and directly slips off, please open the iron cover and use an allen wrench to tighten the inner hexagon nut of the handle.

3. Overload: If the machine is overloaded for more than 10-16 seconds, the machine will automatically shut down. At this time, you can turn off the motor switch first, and then turn on the motor switch to resume normal operation. Similarly, if the power is interrupted during the use of the machine, first turn off the motor switch after the power is received, and then turn on the motor switch to resume normal operation.

4. Feed: Please slow down when drilling and feed, and then increase the feed speed after the drill bit is fully eaten. It is best not to turn off the motor during the drilling process. If the drill bit is blocked in the hole, turn off the motor and use a wrench to slowly unscrew the drill bit.

5. The use of coolant: Please use coolant to cool the drill bit when drilling on a plane. Do not use any coolant when drilling on the top or side of the hole, otherwise the coolant will flow into the hollow drill and cause the magnetic drill press to short-circuit.

Application

Magnetic drill press is suitable for steel structure, shipbuilding, equipment manufacturing, equipment installation, bridge engineering, wind power generation, oil drilling platform, electric power construction, railway manufacturing and other fields.

Three steps of magnetic drilling

- The guide pin accurately keeps the tool at the center of the area to be drilled.

- During the drilling process, the guide pin retracts so that the internal lubrication reaches the cutting teeth.

- When the drilling is completed, the slug/core is automatically ejected from the cutting machine, leaving a precise completion hole.

High-quality precision-designed tools may have tapered inner walls, and these impacts offset the effects of frictional heat accumulation. The accumulation of frictional heat causes the cutter and the waste block generated by the cutting action to expand, so that the block can be quickly ejected when completed.