Tile Tool

Tile Tiling Machine, 100*100cm

Tile Tiling Machine, 80*80cm

Tile Tiling Machine, 60*60cm

Tile Tiling Machine, 12V

Electric Tile Cutter, 1250W

Manual Tile Cutter, 85cm (30 Inch)

Manual Tile Cutter, 40 Inch

Manual Tile Cutter, 48 Inch

Tile Leveling System 1/16 Inch Kit

Wall Tiling Locator, 1 Shaft

Wall Tiling Locator, 3 Shafts

Wall Tiling Locator, 4 Shafts

Grout Joint Tool, 10PCS

Grout Removal Tool, 1 PCS

Grout Removal Tool, 4 Edges

Grout Removal Tool, 3 Metal Balls

3" Grout Removal Tool, Removal Hook

5-in-1 Sealant Removal Tool

10 PCS 8-Inch Tile Grout Saw

Tile Grout Tools, Double Steel Pressed Balls

- 1

- 2

The working principle of tile tiling machine

Tile tiling machine can effectively absorb the tiles through the machine rubber sucker instead of the traditional manual handling, which makes working much convenient and fast. Users' hands do not need to directly touch the moving tiles, avoiding scratching the hands and effectively protecting the operators. At the same time, the principle of motor vibration is used to effectively work on the tile surface to achieve a fast and even working effect. Meanwhile, it avoids the traditional manual hammering that may cause damage to the tiles and the vibration speed and frequency conversion function is equipped and the user can change the vibration frequency at any time.

Why do you need to clean the seams?

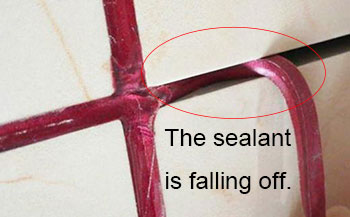

- There is a lot of dust in the gaps between tiles. Such dust will cause poor curing effect of sealant, its adhesion will be affected and the sealant will fall off when it is cured.

- Sometimes cleaning the seams is done, but the depth of sealant is not enough and there will still be a lot of dust and white cement on both sides of the tile gaps, which will affect the efficiency and beauty of sticking the tiles with sealant.

How do you clean seams?

Before cleaning seams, the gaps between the tiles must be cleaned up without leaving any dust and water stains. The detailed operation steps are as follows:

Step 1. Clean the surface of the tiles first and do not leave any dust or water stains.

Step 2. Use grout removal tool to clean out the impurities in the tile gaps. If there is white sealant in the gaps, you need to clean the gaps to a certain depth (at least 3mm depth).

Step 3. Both sides of the tile gap should also be cleaned up, because this position has a great influence on sealant. If there is dust on both sides of the gap, the adhesion of sealant will be weakened and water will easily enter to become moistured.

Step 4. After the gap is cleaned, it is best to use a vacuum to remove dust in gap and on ground.

Attentions to seam cleaning

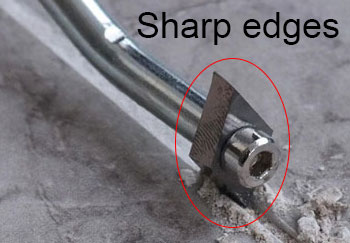

1. Both grout removal tools and tile grout saws are very sharp, so be sure not to hurt both sides of the tiles or your hands during cleaning the seams.

2. Clearing the gaps is a long period project, which can be carried out in stages. It will be very hard to squat for a long time so the owner or professional can do it slowly.

3. Before cleaning the gap, make sure tile gaps are compeletely dry and dry them if wet.