Chamfering Machine

45° Portable Deburring Chamfering Machine

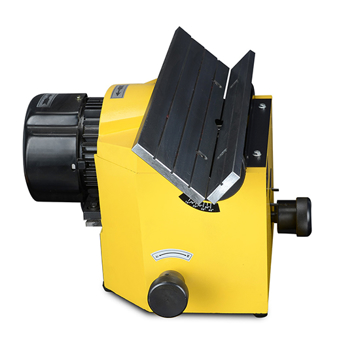

45° Deburring/Chamfering Machine with Mill Cutter

45° Deburring/Chamfering Machine, Straight/Curve

45° Deburring/Chamfering Machine, Semi-Automatic

30°~60° Portable Plate/Pipe Beveling Chamfering Machine

Chamfering and deburring machine is an electric tool used in chamfering, deburring and beveling for pipes or flat plates before welding. For products processed by milling or plane, chamfering machine can also remove burrs.

What is Chamfering?

Chamfering is a process that cut the edges and corners of workpiece into a certain bevel. Chamfering is to remove the burrs on the part due to machining. In addition, in order to facilitate parts assembly, usually, the end of the part will be chamfered.

Chamfer is both a noun and a verb, and it is often used as the name of this cutting. In common usage, the words bevel and chamfer are often interchanged, although they are slightly different in technical usage. Chamfering is often used exclusively to refer to the bevel edge that connects two surfaces.

What is Deburring?

Burr refers to the rough edges, bumps or very small particles left on the object (especially metal) after processing, due to the action of tools or machines. Generally, burrs is left during machining operations, including grinding, drilling, milling, engraving, and turning. Deburring is to remove these excess materials and areas and make the object surface smooth.

The Difference between Chamfering and Deburring

Chamfering and deburring are both important processes in the finishing of metal products. Chamfering is to form bevel, groove and furrow. Deburring is to remove all rough ridges and edges after the product is formed.

Chamfering & Deburring Machine Applications

In metal processing industry, a chamfering and deburring machine is an electric tool that can cut the transition edge between two surfaces of an object. In industrial applications, chamfering is sometimes defined as a bevel. In the industry, processing is usually performed at 45° between two adjacent right-angled surfaces.

Chamfering and deburring machines are usually used in metal processing, woodworking, furniture manufacturing, concrete templates, PVC pipe processing, and printed circuit boards. In addition, it facilitates mechanical assembly and engineering design, providing well-designed structures, shapes and profiles.

In the chamfering process, chamfering and deburring machine can cut bevels and remove burrs on any right-angled edges (such as the ends of holes, rods, bolts and pins).

High quality chamfering and deburring machine with 15°~45° or 30°~60° angle range for your selection. Suitable for various of (end) milling cutter, router bit, drill bit and so on. Please visit the catalog.