Power Trowel

24" Power Trowel, 3HP/4HP Electric Motor

600mm Power Trowel, 5/5.5/6.5HP Gasoline Engine

30" (800mm) Power Trowel, 5/5.5/6.5HP Engine

35" (900mm) Power Trowel, 5/5.5/6.5HP Engine

40" (1000mm) Power Trowel, 5/5.5/6.5HP Engine

46" (1200mm) Power Trowel, 9HP Honda Engine

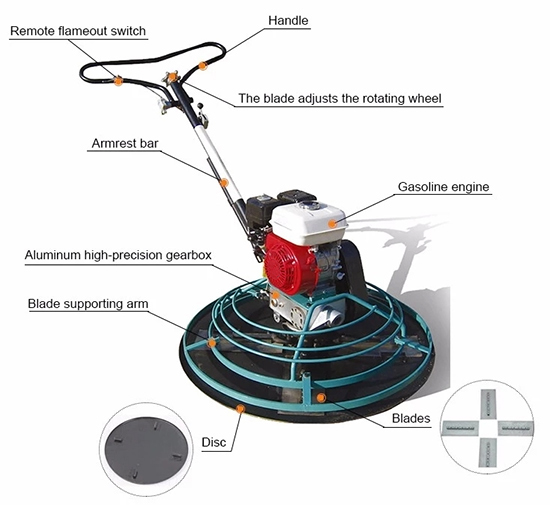

Best walk behind power trowel construction tool for sales, used to finish and polish concrete surface. We offer a wide range of power float machines working diameter form 600mm (24") to 1200mm (46") at lower price. Powered by 4-stroke air cooled single cylinder gasoline engine, model available with 5HP Robin EY20, 5.5HP Honda GX160 and 6.5HP Chinese Loncin GF200. Foldable handle for easy transportation and storage. Heavy-weight design to assure a superior finish. Buy one, you deserve a best and cheap power trowel on Tool.com store.

What is power trowel machine?

Power trowel machine is a high-efficiency troweling machine for building concrete surfaces. It is mainly used for smoothing and calendering concrete surfaces such as road (ground) floors, municipal projects, airports, etc. to improve the density and wear resistance of the ground. The power trowel machine is compact in design, and the deceleration device adopts an arc gear, and its deceleration principle is the same as that of an automobile differential. The concrete trowel can save time and effort, shorten the construction date, and improve the compactness and wear resistance of the concrete surface. Especially in the construction of the concrete surface, the trowel after the vacuum water absorption process is an indispensable construction tool.

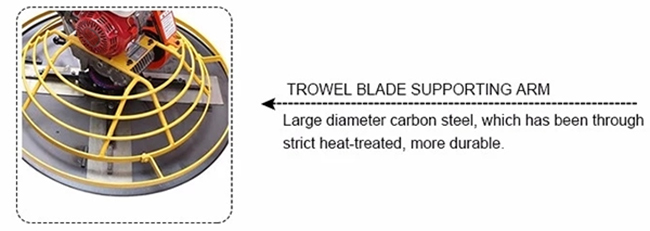

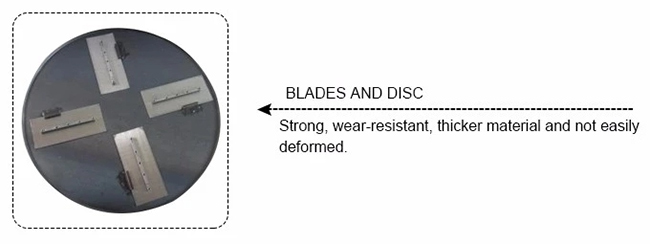

The main structure of the power trowel machine is a spatula rotor driven by a gasoline engine, and a spatula is installed on the bottom of the cross in the middle of the rotor. The inclination direction of the spatula is consistent with the rotation direction of the rotor, and the V-belt is driven by the gasoline engine to rotate the spatula rotor. When operating the power trowel machine, start the trowel first, hold the control handle, push the two handles forward together to move forward, and pull back together to move backward. It can complete 100-300 square meters of work per hour on average, which can increase the work efficiency by more than 30 times compared with manual troweling.

Features of power trowel machine

1. For walk-behind power trowel

The walk-behind power trowel uses manual operation to push the equipment to smooth the ground that has just been poured. Because of its small size and light weight, the walk-behind trowel is very suitable for operation in some small spaces, with flexible response and good stability.

- The walk-behind power trowel reduces labor intensity and improves work efficiency. It has the characteristics of light body and convenient construction in small places, better compaction effect on the ground, and can quickly lift slurry. The mechanical steering operation system is sensitive and easy to control. The engine provides strong and reliable power and stable operation.

- The walk-behind power trowel is suitable for large and small construction sites and can perform indoor and outdoor troweling operations. It is widely used in high-standard workshops, warehouses, squares, airports, parking lots, roads, roads and bridges, and concrete surface lifting and smoothing work. It is the preferred construction tool in concrete construction.

2. For ride-on power trowel

- The relatively rotating double trowel is adopted to make the machine run smoothly, and the operation is safe and labor-saving.

- The structure is compact, small and flexible, and it can be constructed in the kitchens, aisles, terraces, balconies and other places with small plane sizes in residential buildings.

- Due to the small diameter of the trowel, the wiping area at the corners of the room is about half less than that of a single-head floor trowel. It can give full play to the advantages of the ride-on power trowel for troweling a large area of the ground.

- The ride-on power trowel greatly reduces labor intensity and improves work efficiency. It is heavier because of double discs, and has a better compaction effect on the ground. The construction efficiency is significantly higher than other construction machines. It can install two pulp lifting discs at the same time for rapid pulp lifting. The unique handle of the double-disc trowel allows the operator to control the ride-on power trowel safely and freely. The adjustable handle makes the operator feel comfortable and reduces fatigue.

- The ride-on power trowel is mainly aimed at the construction of large-area cement floors and ultra-flat ground. Compared with the hand-held trowel, its construction efficiency is more obvious. The reinforced gearbox and clutch greatly improve the reliability of the machine, making the operation simple and fast.

- The ride-on power trowel has simple structure, easy manufacture, low cost and convenient maintenance.

Power trowel machine operation guide

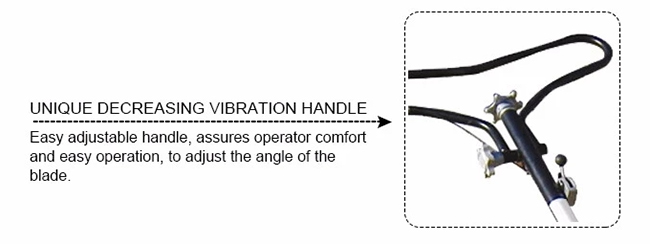

★ Before using the concrete power trowel machine, the debris on the trowel should be cleaned to avoid causing the whole machine to jump and the engineering surface quality problems. Pull out the armrest and adjust the position of the handle to the waist of the operator. Turn on the power, make the wiper rotate in a clockwise direction, not reverse. The moving direction of the trowel is controlled by the change of the position of the handle. The gearbox is a maintenance-free product and does not require oil change.

★ When using the concrete power trowel machine, you can first bounce the line on the concrete surface, so that the guide system installed on the trowel will advance along the bounced line.

★ After turning on the power of the trowel machine, first check whether the electrical appliances of the motor are normal, pay attention to the forward and reverse directions of the motor to prevent leakage.

★ The water tank should be filled with cold water, and the water valve should be opened to ensure sufficient water supply. If you use external water, it can be sprayed directly to the blade for better results.

★ When the concrete power trowel machine is working, start the main motor first, and then slowly rotate the handwheel, so that the blade touches the road, and adjusts to the required depth of the engraving (the depth is generally controlled at about 5 mm). Then start the walking mode and shift the shift to the walking position to make the trowel machine work automatically.

★ When the power trowel machine stops working, you should first turn off the walking motor, turn it to the neutral position, and turn the lifting hand wheel at the same time to keep the blade off the road and close the cooling water valve.

★ The machine should be cleaned frequently, especially the main shaft bearing parts, grease should be injected every day to ensure that the machine works normally.

Safety tips

1. Before use, check whether the electric motor (engine), electrical switch, cable and wiring of the trowel are normal and whether they meet the regulations. The machine should be equipped with a leakage protector.

2. Carry out a trial run after the power is turned on. The blades rotate in a clockwise direction and must not be reversed.

3. Operators should wear insulated shoes and insulated gloves. The cable should be picked up by auxiliary personnel. The auxiliary personnel should also wear insulated shoes and insulated gloves. Pay attention to prevent the cable insulation from being broken and electric shock accidents.

4. If the power trowel is malfunctioning, it must be shut down and cut off the power supply before maintenance.

5. The concrete power trowel should be stored in a dry, clean and non-corrosive environment. The handle should be placed in the specified position. And the power float should not be loaded or unloaded brutally.