In the world of mechanics, engineering, and automotive work, precision is key. Whether you're adjusting the valve clearance on an engine, measuring the gap in a machine, or checking the thickness of a material, a feeler gauge can be an invaluable tool. But what exactly is a feeler gauge, and how does it work? In this blog, Tool.com will explore the purpose, uses, and advantages of a feeler gauge, and why this simple tool is a must-have for precise measurements in various fields.

Understanding the Feeler Gauge

A feeler gauge is a measuring instrument made up of a set of thin, flat metal blades of varying thickness. These blades, usually made of high-carbon steel or stainless steel, are designed to measure small gaps or clearances between two parts. The blades are often marked with their thickness, either in thousandths of an inch or millimeters, allowing for precise measurement. They are commonly used in automotive, mechanical, and engineering applications where accurate gap measurements are crucial.

The tool is called a “feeler” gauge because it works by feeling the gap between two surfaces. The user selects a blade of the appropriate thickness and slides it into the gap. If the blade fits snugly, it provides an accurate measurement of the gap width.

Common Uses of a Feeler Gauge

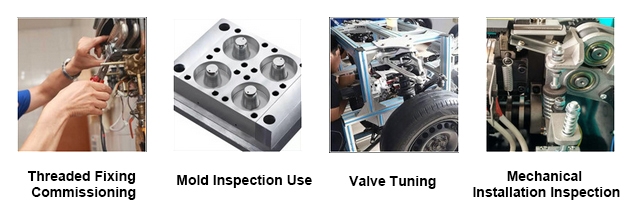

Feeler gauges are most commonly used in fields where precise measurements are necessary. Some of the primary applications include:

- Engine Maintenance: One of the most common uses of a feeler gauge is in automotive engine maintenance. For example, when adjusting the clearance between engine valves and rocker arms, a feeler gauge is used to ensure the gap is within the recommended range for optimal engine performance.

- Carburetor Tuning: Feeler gauges are also used when tuning carburetors. By adjusting the gap between parts in the carburetor, mechanics ensure the engine runs smoothly and efficiently.

- Brake Components: In the automotive industry, feeler gauges can be used to check the thickness of brake pads or measure the gap between brake components. This ensures the brakes are working at their best and helps prevent safety issues.

- Machinery and Equipment: Feeler gauges are often used to measure small gaps in machinery and equipment. For example, they help check the alignment of parts, ensuring smooth operation and preventing wear and tear.

- Gasket Installation: When installing a gasket, feeler gauges can be used to measure the clearance between the mating surfaces, ensuring a proper fit that prevents leaks.

- General Engineering: In engineering and manufacturing, feeler gauges are essential for checking clearances between moving parts, such as bearings, shafts, or gears.

Working Principle of a Feeler Gauge

Using a feeler gauge is quite straightforward. Here’s how it works:

- Choose the Correct Blade: Feeler gauge sets come with a range of blades of different thicknesses. Start by selecting a blade that’s close to the expected gap size.

- Insert the Blade: Insert the selected blade into the gap between two parts. The blade should fit snugly but with a slight resistance.

- Test for Fit: If the blade fits too easily, it means the gap is larger than the blade thickness. If the blade doesn’t fit, the gap is smaller, and you’ll need to try a thinner blade. Continue this process until you find a blade that fits comfortably without forcing it.

- Read the Measurement: Once you find the blade that fits correctly, you can read the thickness marked on it. This is your measurement of the gap or clearance.

Advantages of Using a Feeler Gauge

Feeler gauges are highly valued in many industries because of the numerous advantages they offer:

- Precision: Feeler gauges can measure small gaps with extreme precision, often to the thousandth of an inch or millimeter. This allows for highly accurate adjustments and measurements.

- Durability: Made from high-strength materials like stainless steel or carbon steel, feeler gauges are built to last, even in harsh conditions.

- Versatility: These gauges are useful in a variety of applications, from automotive repairs to machinery maintenance, making them a versatile tool in any workshop.

- Affordability: Compared to other precision measuring tools, feeler gauges are relatively inexpensive, offering excellent value for anyone who needs accurate measurements.

- Ease of Use: Feeler gauges are simple to use, requiring minimal training or experience. Their straightforward design makes them ideal for both professionals and DIY enthusiasts.

Conclusion

In conclusion, a feeler gauge is an essential tool for anyone who requires accurate measurement of small gaps or clearances. From automotive maintenance to engineering applications, this humble tool plays a vital role in ensuring precision and proper functioning in various mechanical systems. Whether you are a professional mechanic, a hobbyist working on a DIY project, or an engineer maintaining critical machinery, a feeler gauge is an indispensable tool that should be a part of your toolkit.

By selecting the right blade and using it properly, you can achieve highly accurate measurements that will improve the performance, safety, and longevity of your equipment. The feeler gauge is an affordable, reliable, and efficient solution for gap measurement, helping you achieve the precision you need for your work.