Wholesale manual control electric wall cutting saw machine designed to cut the door, window or elevator hole and other large area wall cutting. 16 inch cutting depth and 39 inch durable diamond saw blade, powered by 6450 watt powerful copper motor.

Specification

| Model |

T-JL-1000A |

| Saw Type |

Circular Saw |

| Max. Cutting Depth |

400mm (16") |

| Voltage |

220V AC |

| No-load Speed |

400 r/min |

| Power |

6450W |

| Frequency |

50Hz |

| Standard Saw Blade |

1000mm (39") |

| Weight (with package) |

112 kg |

| Dimension |

Main Engine: 560*530*840 mm (22"*21"*33") |

| Protected Hood: 1090*120*1090 mm (43"*5"*43") |

| Guide Rai: 1220*170*90 mm (48"*7"*3.5") |

| Application |

Wall, Pillar, Building Renovation, Road, Bridge and Railway |

Features

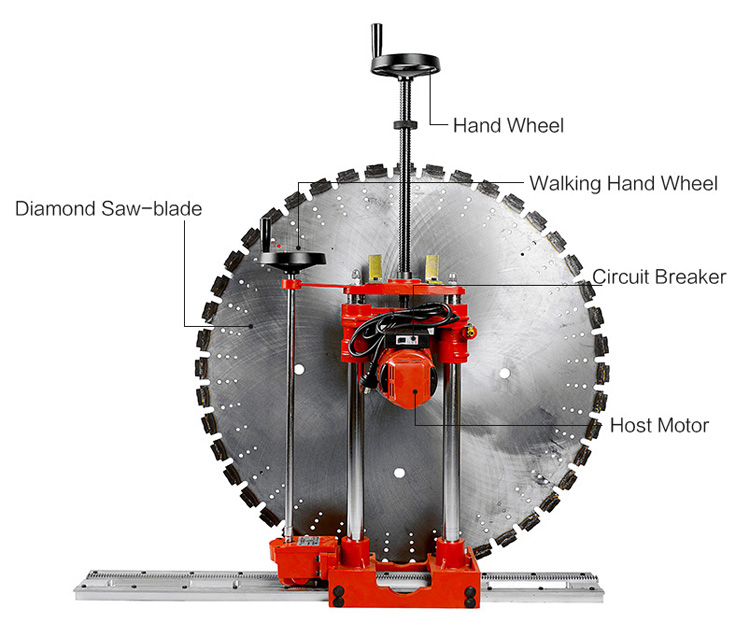

1. Stainless Steel Chuck Plate: Chuck plate with dewatering orifice made of steel could connect to the water pump to dedust.

2. Protected Hood: Used with stainless steel chuck, effectively prevent dust droplets, sewage splashing, and accidental occurrence of saw blade operation.

3. Diamond Saw Blade: Thicken steel sharp cutting head, durable, high strength, and uneasy to transform, suitable for granite, marble, high standard concrete etc.

4. Pure Copper Motor: Industrial grade special motor with durable and stable output, more powerful horsepower and more efficiency.

5. Circuit Breaker: Automatic trip power off after overload, guarantee security. After tripping, it could be reused when the air switch closed again.

6. Labor-saving Hand Wheel: Aluminum wheel, more durable. Folding plastic handle, user-friendly design.

7. Steel Gear Track: Made of aviation grade aluminum, high density, light weight, easy to fix. The standard is 1.2m, 0.8~2.4m could be customized based on your demand.

Machine Details

Wall Cutter Accessories

Power Plug Selection

(Note: Power plug can be customized based on your local machine standards)

Tips for hand control wall cutter machine

The wall cutting machine is a widely used construction cutter, which has the advantages of convenient carrying, simple operation, stable structure, small volume and light weight. If you want to use the wall cutting machine correctly, you must follow the process and methods to ensure the smooth cutting of the wall without damaging the overall wall. The staff who use the wall cutting machine must be professional and have a certain understanding of the machine and operate it correctly and be able to find and deal with the problems caused by the machine in time. If you want the wall cutter to reach the ideal state, be sure to buy through formal channels and buy those well-known and good-quality types. Pay attention to personal safety when using the wall cutter. The wall cutter is dangerous. Before use, check whether all parts are installed and keep a certain safe distance when cutting and wear protective equipment. After using the wall cutting machine, you must unplug the power cord and turn off the switch in time and the continuous use time cannot be too long.