The splitting tool is the cutter head of hydraulic nut splitter, so it is needs to used with a hydraulic hand pump or electric pump for power source.

Specification

| Model |

T-NC-1319 |

T-NC-1924 |

T-NC-2432 |

T-NC-3241 |

| Output Force |

5 Ton |

10 Ton |

15 Ton |

20 Ton |

| Nut Range |

Nut Specification |

M6-M12 |

M12-M16 |

M16-M22 |

M22-M27 |

| Opposite Side Length |

10-19mm |

19-24mm |

24-32mm |

32-41mm |

| Weight |

1.2 kg |

2 kg |

3 kg |

4.4 kg |

| Recommended Pump |

Hydraulic Hand Pump: T-CP-700 (10,000 psi, 900 cc Oil Reservoir)

Hydraulic Electric Pump: T-HHB-700A (10,000 psi, 750W), T-QQ-700 (10,000 psi, 1.2kW) |

Features

- The hydraulic nut splitter can easily split and cut corroded nuts, compact structure, portable and easy to operate.

- Split hydraulic design, equipped with ZG3/8” quick connector and dust cap, which is convenient for connecting various hydraulic pumps.

- The spring automatically resets. Nut splitter tool also available in explosion-proof environment.

Hydraulic Nut Splitter Instructions

- Open the oil plug of hydraulic hand pump, fill with 20# oil or hydraulic oil, and close the unloading valve.

- Sleeve the hole of hydraulic nut splitter head into nut and place it level.

- Press the hydraulic hand pump to push the splitting cutter out and advance to the nut. When splitting cutter is pushed into one half of the nut, hand pump must be pressed carefully to avoid excessive force, which may cause the splitting cutter to speed too fast and damage bolt threads

- When hearing a cracking sound, it means that the nut has been broken, and stop pressing hand pump at this time.

- Unscrew the unloading valve, reset the splitter, remove the hydraulic nut splitter, and the work is over.

Nut Splitting Operation Steps

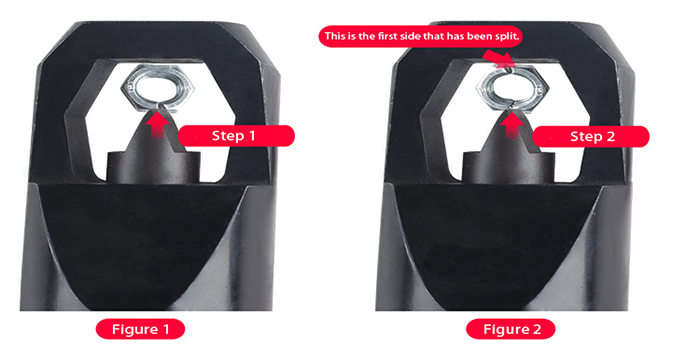

- First, split the first side. Align the cutter head at the middle of nut to split it. (As shown in Figure 1)

- Split the opposite side. Adjust direction, align the cutter head at the middle of nut, to cut the other side. Both sides need to be symmetrical. (As shown in picture 2)

Tips: Hydraulic nut splitter applications.

As we all know, nut is a tool widely used in industrial production. In an open high temperature or corrosive environment, some nuts will be rusted, and some nuts thread will be damaged due to being hit. In short, when these problems occur, it is very difficult to disassemble nuts.

In the past, nuts and bolts are usually cut off simultaneously by gas welding or electric welding. However, in some special working conditions, sometimes it is strictly forbidden to use fire (electric) welding operations (such as pulverized coal silos of power plants, high-pressure and high-temperature pipelines of oil pipelines, etc.). It is helpless to replace nuts and bolts.

At this time, the hydraulic nut splitter can be used without fire, without electricity, and does not damage the bolt threads. The problem of disassembly and replacement of bolts and nuts can be solved simply, quickly, safely and efficiently.