Gas Monitor

Portable Nitrogen (N2) Gas Tester, 0 to 100% VoL

Portable Nitrogen Dioxide (NO2) Gas Tester, 0 to 100/500/1000 ppm

Portable Oxygen (O2) Gas Monitor, 0 to 30% VOL

Portable Ozone (O3) Gas Monitor, 0 to 100/500/1000 ppm

Gas monitors are vital in modern industry, environmental monitoring, and home security. Whether detecting toxic gas leaks in a factory or real-time monitoring of carbon monoxide in the home, gas detectors provide accurate and instantaneous results to safeguard people's lives and environmental health. With the advancement of science and technology, the types and functions of gas detectors are constantly enriched, from single gas detection to comprehensive detection of multiple gases, from portable devices to fixed monitoring systems, these instruments are widely used in various fields. This catalog will introduce in detail the types of gas detectors, application scenarios, technical parameters, and purchasing guidelines to help you find the most suitable gas detector for your needs.

Through this catalog, you can understand the working principle of gas detectors, the characteristics of various types of gas sensors, as well as how to make a reasonable selection and configuration in practical applications. Whether you are engaged in industrial safety, environmental protection, or concerned about home safety, this catalog will provide you with comprehensive references and help.Tool.com has carefully organized this catalog, aiming to provide you with the most authoritative and latest gas detector product information to help you with your safety monitoring work.

A gas tester is a kind of instrumentation tool for gas leakage concentration detection, which includes: portable gas detectors, handheld gas detectors, fixed gas detectors, online gas detectors, and so on. Gas sensors are mainly utilized to detect the type of gas present in the environment. Gas sensors are sensors that are used to detect the composition and content of a gas.

It is generally accepted that the definition of a gas sensor is based on the classification of the target to be detected, that is to say, any sensor that is used to detect the composition and concentration of a gas is called a gas sensor, regardless of whether it is used by a physical method, or by a chemical process. For example, sensors that detect gas flow are not considered gas sensors, but thermally conductive gas analyzers are important gas sensors, even though they sometimes use roughly the same detection principle.

Gas Monitor Working Principle

The common infrared gas detector is used as an example to illustrate the principle of a gas detector: the measurement of this absorption spectrum identifies the type of gas, and the measurement of the absorption intensity determines the concentration of the gas being measured. Infrared detectors use a wide range, not only analyzing the composition of the gas but also analyzing the solution composition, high sensitivity, and rapid response can be online continuous instructions but also can be composed of regulating systems. Commonly used in industry infrared gas detector detection is part of the detection by two side-by-side structures of the same optical system.

One is the measuring chamber and the other is the reference chamber. The two chambers through the cut light plate to a certain period at the same time or alternately open and close the optical path. When the gas to be measured is introduced into the measuring chamber, the light with the wavelength specific to the gas to be measured is absorbed, so that the luminous flux through the optical path of the measuring chamber and into the infrared receiving gas chamber is reduced. The higher the gas concentration, the lower the luminous flux into the infrared receiving gas chamber; while the luminous flux through the reference chamber is certain, the luminous flux into the infrared receiving gas chamber is also certain.

Therefore, the higher the concentration of the gas to be measured, the greater the difference in luminous flux through the measurement chamber and the reference chamber. This difference in luminous flux is projected into the infrared receiving gas chamber with the amplitude of a certain period of vibration. The receiving gas chamber is separated into two halves by a metal film a few microns thick, in which a gas with a large concentration of the component to be measured is enclosed, and all the infrared rays injected into the chamber are absorbed within the absorption wavelength range so that the pulsating luminous flux is changed into a cyclic change of temperature, and then the change of temperature is converted into a change of pressure according to the gaseous equation, and then detected by capacitive sensors, and the concentration of the gas to be measured is indicated after amplification processing.

Gas Monitor Usage

Gas detectors can detect hydrogen sulfide, carbon monoxide, oxygen, sulfur dioxide, phosphine, ammonia, nitrogen dioxide, hydrogen cyanide, chlorine, chlorine dioxide, ozone and combustible gases, and other gases, widely used in petrochemicals, coal, metallurgy, chemical industry, municipal gas, environmental monitoring, and other places of on-site detection. It can realize the measurement needs of special occasions. It can be used for gas concentration detection or leakage detection in pits, pipelines, tanks, confined spaces, and so on.

Detection Unit of Gas Detector

- Magnetic Oxygen: This is the core of the Magnetic Oxygen Analyzer, but it has also been “sensorized”. It is prepared by utilizing the principle that oxygen in the air can be attracted by a strong magnetic field. This sensor can only be used for the detection of oxygen, only nitrogen oxides in the atmosphere can have a minor effect, but since these interfering gases are often present in very small amounts, the selectivity of the magnetic oxygen analyzer technology is almost unique.

- LEL: The “LEL” is the Lower Explosive Limit. Combustible gases in the air in the presence of an open flame explosion of the lowest concentration, known as the lower explosion limit - referred to as % LEL. English: Lower Explosion Limited. combustible gases in the air in the presence of an open flame explosion of the highest concentration, known as the upper explosion limit - referred to as % UEL. English: Upper Explosion Limited. Explosion Limited. so what is the lower explosion limit? Combustible gas concentration is too low or too high it is not dangerous, it is only mixed with air to form a mixture or more precisely meet the oxygen to form a certain proportion of the mixture that will burn or explode. The measurement range of various combustible gas detectors is 0-100% LEL. Stationary combustible gas detectors usually have two alarm points (related to the model of the alarm host): 10% LEL for the first alarm, and 25% LEL for the second alarm.

- PPM: PPM is a method of expressing the concentration of a solution (mass fraction of solute), ppm means parts per million. For solution: 1 liter of aqueous solution has 1/1000 milliliter of solute, and the concentration (solute mass fraction) is 1 ppm. for gas: one of the ways to express the concentration of pollutants in the ambient atmosphere (air). Volumetric concentration: the volume of a pollutant contained in one million volumes of air, i.e. ppm. most gas detectors measure the concentration of a gas as a volumetric concentration (ppm).

Classification of Gas Monitors

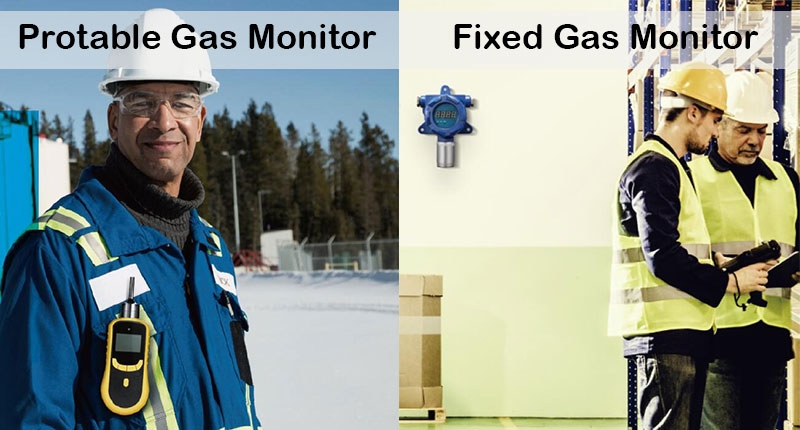

The way of use can be divided into fixed gas tester and handheld gas detector.

- According to the number of detectable gases can be divided into a single gas detector and multiple gas detector

- According to the principle of the gas sensor can be divided into infrared gas detector, thermal magnetic gas detector, electrochemical gas detector, semiconductor gas detector, ultraviolet gas detector, and so on.

Gas Monitor Service Life

The service life of a gas detector depends mainly on its main component: The sensor.

We also know that there can not be a sensor that can detect all the gases, to meet all the requirements of a variety of gases, and a variety of environments using the sensor is not the same, can be roughly divided into: for the detection of toxic gas concentration sensors and sensors used to detect the explosive concentration of combustible gases. Most of the sensors used to measure the concentration of toxic gases are electrochemical sensors, which are sensors based on electrochemical principles of work, the main thing that affects its life is the electrolyte, and the electrolyte will be consumed and can no longer work properly after 2 to 3 years of general sensors.

Most of the sensors used to detect the concentration of combustible gases are catalytic combustion sensors, which have a service life of 3 to 5 years.

Selection Method

Confirm the type of gas to be detected and the concentration range:

Each production department encounters different types of gases. Consider all possible scenarios when selecting a gas detector. If methane and other less toxic alkanes are predominant, a LEL detector is the most appropriate choice. This is not only because the LEL detector is simple and widely used, but also because it is easy to maintain and calibrate. If there are carbon monoxide, hydrogen sulfide, and other toxic gases, it is necessary to give priority to a specific gas detector to ensure the safety of workers.

If more organic toxic and hazardous gases are present, taking into account their lower concentrations that may cause personnel poisoning, such as aromatic hydrocarbons, halogenated hydrocarbons, ammonia (amines), ethers, alcohols, lipids, etc., the photoionization detector introduced in the previous chapter should be selected, and never use a LEL detector to cope with the situation, which may lead to injuries or deaths.

If the gas type covers the above categories of gases, choosing a composite gas detector may achieve twice the result with half the effort.

Determine the Application

Different industrial environments have different types of gas detectors to choose from.

Fixed gas detector

- This is the detector used more in industrial installations and production processes. It can be installed at a specific detection point to detect a specific gas leak. Fixed gas detector is generally a two-body type, there are sensors and transducers composed of the detection head as a whole installed in the detection site, and there are circuits, power supply, and display alarm device composed of the secondary instrumentation as a whole installed in a safe place, easy to monitor.

- Its detection principle as described in the previous section, is only in the process and technology is more suitable for fixed detection required by the continuous, long-time stability and other characteristics. They should also be selected according to the type and concentration of the gas on-site, but also pay attention to the installation of them in the specific gas that is most likely to leak parts, such as the specific gravity of the gas to choose the most effective height of the sensor installation and so on.

Portable gas detector

- Due to the portable gas tester being easy to operate, small in size, and can be carried to different production sites, the electrochemical detector using an alkaline battery power supply, can be used for 1000 hours of continuous use. New LEL detectors, PID, and composite instruments using rechargeable batteries (some have been used without memory of nickel-metal hydride or lithium-ion batteries), so that they can generally work continuously for nearly 12 hours, so, as this type of instrument in various types of factories and health departments are increasingly widely used.

- If it is in the open occasions, such as an open workshop use this kind of instrument as a safety alarm, you can use the diffusion gas detector to wear, because it can be continuous, real-time, and accurately display the concentration of toxic and hazardous gases on the scene. Some of these newer instruments are also equipped with vibration alarm attachments to avoid inaudible audible alarms in noisy environments, and computer chips to record peaks, STELs (15-minute short-term exposure levels), and TWAs (8-hour statistically weighted averages), which provide specific guidance for worker health and safety.

In the case of workplaces where confined spaces are being entered, such as reaction tanks, storage tanks or vessels, sewers or other underground pipes, underground facilities, agricultural confined grain silos, railroad tank cars, shipping holds, tunnels, etc., testing must be done before personnel entry and outside of the confined space. In this case, it is necessary to choose a multi-gas detector with a built-in sampling pump. If there are a variety of gases in the environment, choosing a composite gas detector may achieve twice the result with half the effort.

Combined Gas Detectors

The composite multi-gas detector can be equipped with multiple gas sensors in one instrument, so it has the characteristics of small size, lightweight, fast response, and simultaneous multi-gas concentration display. What's more, Yi Yang composite multi-gas detectors are cheaper and easier to use than multiple single diffusion gas detectors. It should be noted that when choosing this type of detector, it is best to choose the instrument with the function of switching each sensor individually, to prevent the damage of one sensor from affecting the use of other sensors.

In today's increasingly security-conscious social environment, gas detectors have become an indispensable safety tool. Whether in industrial production, environmental monitoring, or home protection, gas detectors can provide you with timely and accurate information on gas concentrations to prevent potential hazards. Through this catalog, you will not only get a comprehensive understanding of the features and application scenarios of the different types of gas detectors available on the market but also get practical advice on purchasing to ensure that you choose a product that meets your practical needs and offers good value for money.

This catalog provided by Tool.com brings together the most up-to-date gas detector product information in the market, hoping to provide you with a comprehensive reference and help for your safety monitoring. We hope that this catalog will help keep you safe in the future, no matter what kind of environment or challenge you are facing. Choosing the right gas detector will bring you a higher level of safety and peace of mind in your life and work.