Cheap price self leveling laser level with 5 green laser lines, 360° rotating base, both DC (3 pcs 1.5V AA batteries) and AC (100-240V /50-60Hz) available for this green laser level tool, IP54 waterproof protection grade enables users to work well in a hazardous working environment.

Specification

| Model |

T-SL-05 |

| No.of Laser Lines |

5 |

| Leveling Type |

4 vertical line, 1 horizontal line, 1 plumb dot, 5 bright dots |

| Laser Wavelength |

635nm |

| Self-Leveling Range |

±3° |

| Launch Angle |

≥120° |

| Horizontal Accuracy |

5m±1mm |

| Vertical Accuracy |

5m±1mm |

| Plumb Dot Accuracy |

±1mm at 1.5m |

| Line Width |

2mm |

| Line Color |

Emerald green |

| Power Supply |

3 x AA batteries or AC power |

| IP Rating |

IP54 |

| Operation Temperature |

0℃~40℃ |

| Battery Type |

Digital LCD rechargeable lithium battery (8 hours standby) |

| Function Key |

Fingerprint touch buttons |

| Laser Head |

Made in Germany |

| Laser Tube Life |

10 years |

| Outdoor Visible Distance |

About 15m |

| Indoor Visible Distance |

About 15m~40m |

| Application |

Ceiling, home decoration, door and window installation, etc |

| Weight |

2.5kg |

Details

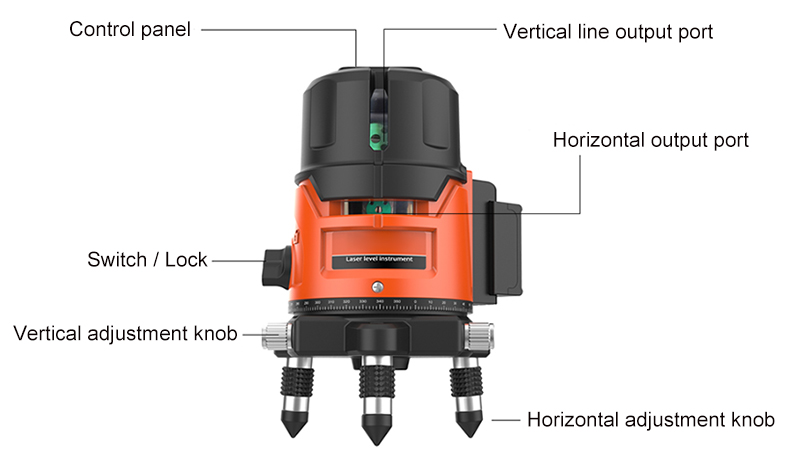

5 Line Laser Level Diagram

Tips: Zero calibration method of laser level

Before use, check whether the dial indicator is in the controlled range. In order to avoid measurement errors caused by the inaccurate zero position of the level, the zero position of the level must be calibrated or adjusted before use.

Zero calibration method of the spirit level: Place the spirit level on a stable and roughly horizontal plate (or machine tool rail), after the bubble stabilizes, read at one end (such as the left end) and set it to zero. Turn the level meter 180 degrees again, and keep it in its original position. After the bubble is stable, the original end (left end) is still reading A division, then the zero position error of the level meter is half A division.

If the zero error exceeds the allowable range, you need to adjust the level meter zero adjustment mechanism (adjust the screw or nut to reduce the zero error to within the allowable value. For non-specified adjustment screws and nuts, do not twist at will. The working surface and the plate must be wiped clean first before adjusting the level. After adjustment, the screws or nuts must be tightened).