Diamond Core Drill

Diamond Core Drill Machine, 90mm, 1400W

Diamond Core Drill Machine, 130mm, 1650W

Diamond Core Drill Machine, 150mm, 1800W

Diamond Core Drill Machine, 160mm, 3200W

Diamond Core Drill Machine, 180mm, 3380W

Diamond Core Drill Machine, 200mm, 3650W

Diamond Core Drill Machine, 230mm, 3880W

Diamond Core Drill Machine, 250mm, 3950W

Diamond Core Drill Machine, 300mm, 4350W

Diamond Core Drill Machine, 350mm, 4680W

Diamond Core Drill Machine, 400mm, 4980W

Diamond Core Drill Machine, 500mm, 6880W

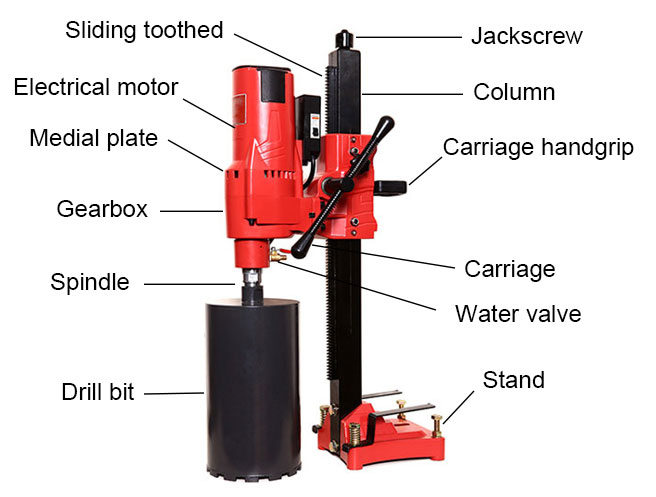

Introduction to diamond core drill

Introduction to diamond core drill

Diamond is the hardest natural material in the world, which is ideal for creating holes on various materials including concrete, metal and glass. While diamond drilling is a form of drill core that uses a rotating drill bit with a diamond drill bit to make accurately measured openings. A diamond core drill based on this technique, also called concrete drilling machine, is a precision construction tool that can create clean and accurate holes.

Unique Features

- Since diamond core drill embraces a non-percussive technique, the integrity of the surrounding structure is maintained during drilling. Each diamond core drill bit injects water into the drive shaft to ensure that there is no dust in the working space.

- All the full copper motors of diamond core drill machines operate with wide ranging rated power (1400W, 1650W...to 6880W), diameter hole capacity (90mm, 130mm...to 500mm) and offer various step-less speed.

- The diamond core drill is designed with safe and reliable devices, such as friction clutch, external carbon brush, soft starting device, overcurrent protection, cooling water connection as well as pure copper power cord and features in high efficiency, lighter and steadier material, smooth & accurate holes, flexible mobility and reliable saftety.

- The diamond core drills for sale at Tool.com offer wet/dry dual use, portable/vertical operation mode, high quality, factory price and free shipping.

Wide Application

The dual use drilling machine can be operated in either vertical or horizontal directions as required, is used to drill holes on reinforced concrete, rocks, masonry, ceramics, glass and fire-proof materials, and is widely applicable for quality inspection, construction of airport runway, railway, bridges and tunnel, and installation of water, electricity, heat and gas.

Troubleshooting of Diamond Core Drill

|

Symptoms |

Immediate actions |

Possible cause |

Remedy |

|

Drill bit sticks. |

Cut off the power. |

1. There are water, sand or stone in the concrete to make the center of drill bit offset. |

Use a wrench to slowly turn and pull out the drill bit, increase the water supply pressure. |

|

2. Excessive clearance between column and slide block. |

Check machine frame to adjust the clearance. |

||

|

3. Serious radial wear of the drill. |

Replace the drill rig. |

||

|

4. Very few cooling water or no water. |

Add enough water. |

||

|

Drilling capacity declines. |

Check the drill bit. |

1. The new drill rig is not regrinded. |

Drill several holes to regrind the bit. |

|

2. Drill bit quality is not qualified. |

Replace the drill rig. |

||

|

3. Drill bit wears. |

Replace the drill rig. |

||

|

4. Drill bit barrel is tapered or deformed. |

Replace the drill rig. |

||

|

5. Drill bit jumps too much. |

Replace the drill rig; check the drill spindle'movement; repair the drill bit positioning; install the drill bit in place. |

||

|

Check drainage. |

1. Low water supply pressure. |

Fix the rack. |

|

|

Check the hole drilling. |

1. The center line of the drill bit is not parallel to the center line of the guide rail. |

Repaire the rack. |

|

|

2. The quality of the concrete is not high, there are small stones. |

Clean the hole wall and take out the stones and sands. |

||

|

3. The power socket is connected incorrectly. |

Have an electrician for inspection. |

||

|

4. The power supply is not grounded. |

Connect the ground wire. |

||

|

5. The charged body is not well insulated from the shell. |

Repair is needed. |

||

|

Too much motor sparks. |

Cut off the power. |

1. The brush holder is loose.and the commutator surface is seriously damaged. |

Fasten the brush holder. |

|

2. The brush is severely worn. |

Replace the brush. |

||

|

3. The surface of the commutator severely damages the brush and commutator connection. |

Commutator needs reparing or replacement. |

||

|

4. The rotor and stator are faulty. |

Repair is needed. |

||

|

The no-load current is too large. |

Cut off the power. |

1. Electromechanical failure. |

Repair is needed. |

|

The no-load sound is abnormal. |

Cut off the power. |

1. The power supply voltage is too high. |

Adjusted the power supply voltage. |

|

2. Drill bit is not installed in place. |

Tighten the drill bit to make sure it is installed in place. |

||

|

High vibration. |

Cut off the power. |

1. The fan blade is damaged and deformed. |

Repair is needed. |

|

2. Electromechanical failure. |

Repair is needed. |

||

|

The motor does not rotate after power-on. |

Cut off the power. |

1. Power supply voltage is too low. |

Adjusted power supply voltage to standard one. |

|

2. The motor is burned out. |

Repair is needed. |

||

|

The motor temperature is too high. |

Cut off the power. |

1. Fan blade is loose. |

Repair is needed. |

|

2. Bearing damages. |

Repair is needed. |

||

|

3. The motor failure. |

Repair is needed. |

||

|

The motor rotates but the main shaft doesn't when drilling. |

Cut off the power. |

1. The gear teeth of the rotor shaft are broken. |

Repair is needed. |

|

2. Reducer failure and clutch is loose. |

Tighten the clutch nut and replace the clutch plate. |

||

|

The core cannot be taken out of the drill bit barrel. |

Cut off the power and remove the drill bit. |

1. There are sands, iron filings, etc. between the drill bit barrel and the core. |

Rinse the inner barrel of drill bit with water and then carefully remove the core. |

|

2. The core burrs are too large and stuck on the inner wall of the drill bit. |

Rinse the inner tube of the drill bit with water and then carefully remove the core. When the hole is about to drill through, the drill must be slow during when drilling. |